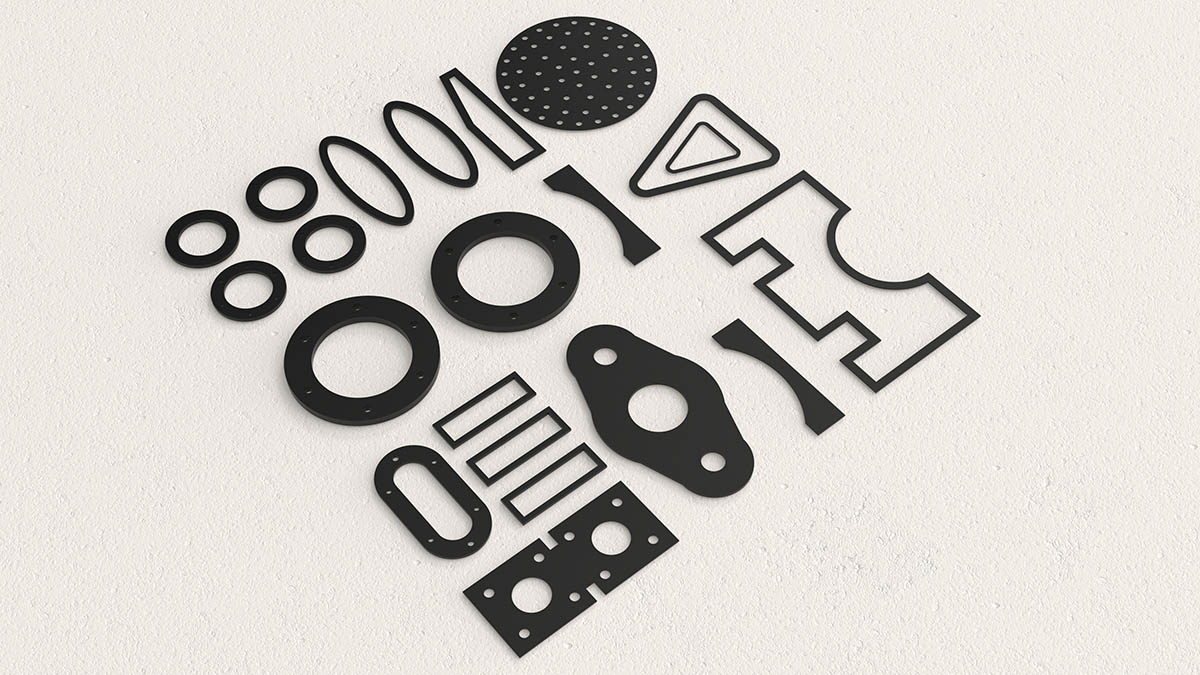

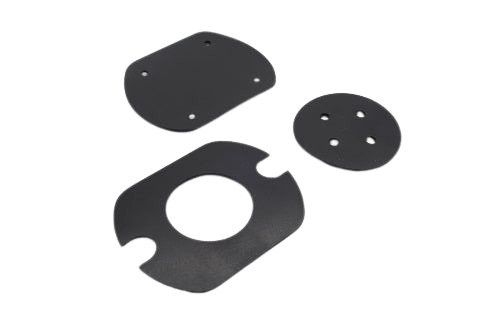

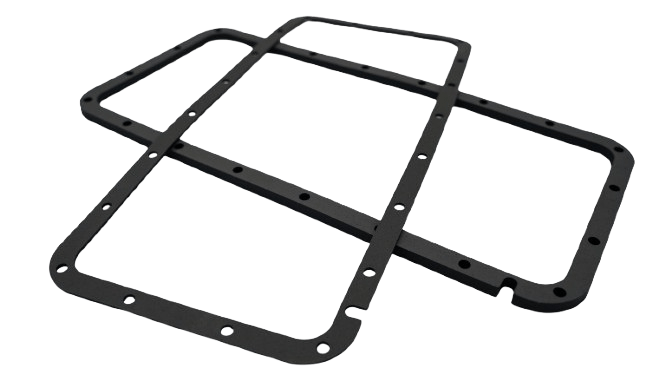

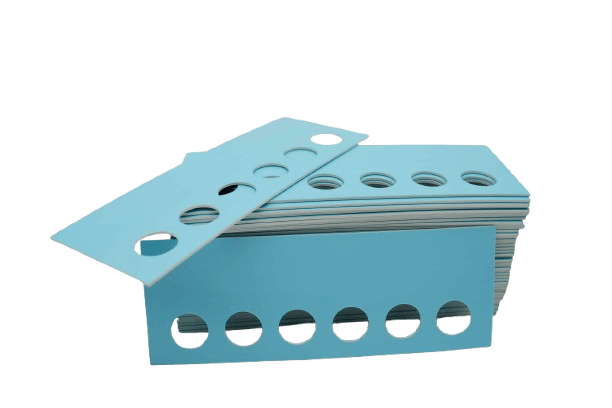

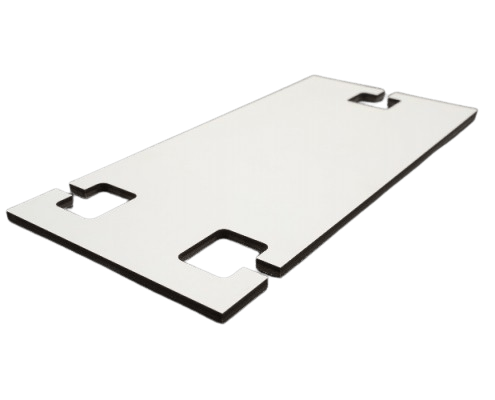

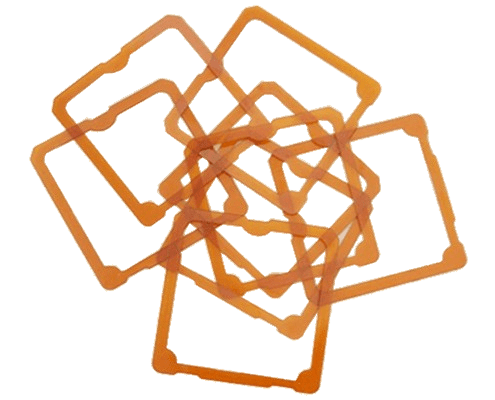

NBR (Nitrile Rubber)

Rubber

NBR, or nitrile butadiene rubber, is a synthetic rubber known for its excellent resistance to oils, greases, and fuels. Thanks to these properties, NBR is widely used in the automotive industry, mechanical engineering, and the oil and gas sector. The material offers a good balance between flexibility, mechanical strength, and chemical resistance.

Well-known trade names for NBR include Buna-N, Perbunan®, Nipol®, and Europrene®. These grades are used worldwide in applications where oil resistance and durability are essential.

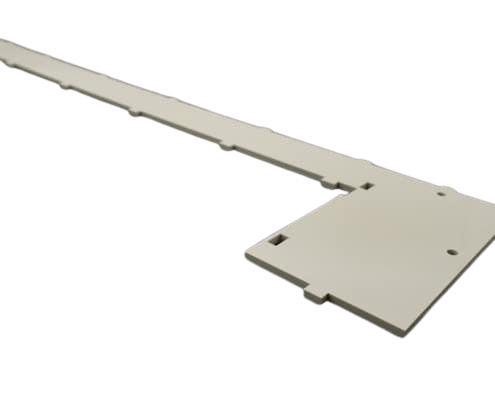

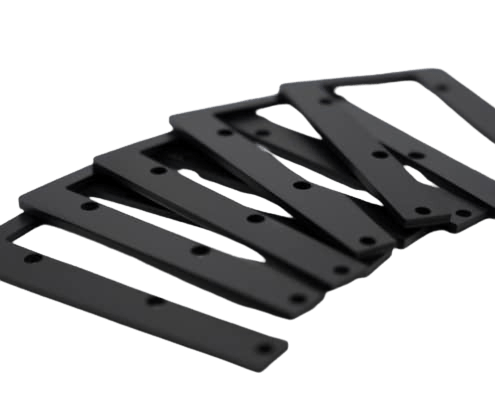

- Laser cutting

- Milling